Darde FATP - Exceed Your Highest Expectation

Experience the Best with Darde FATP

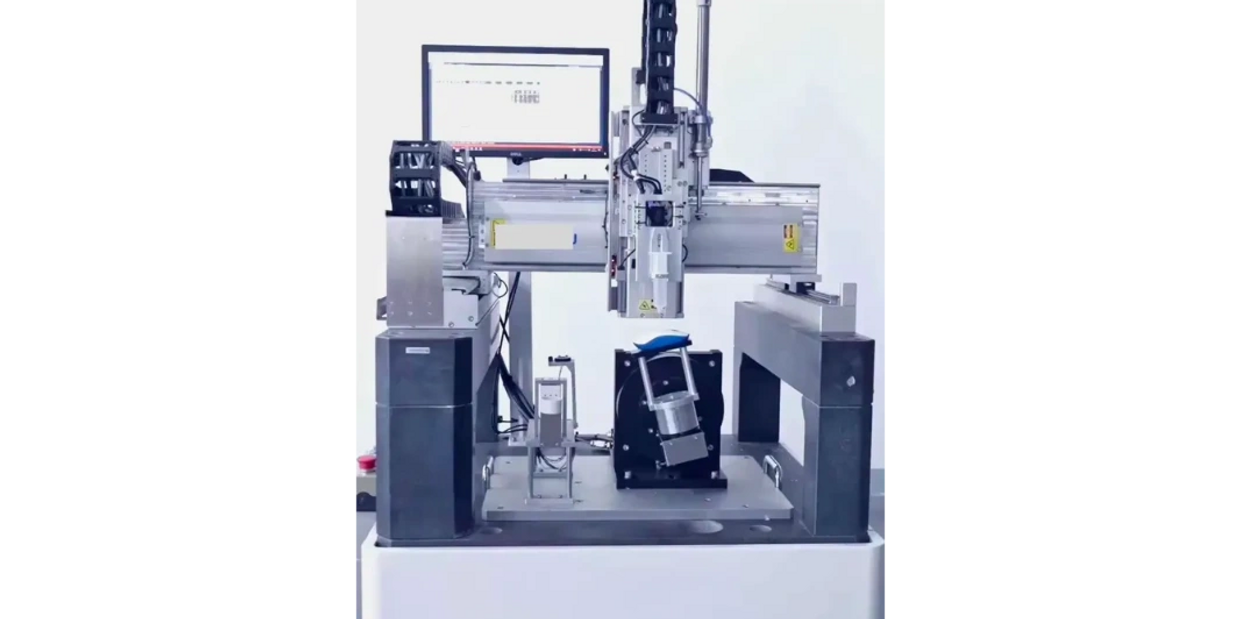

Our FATP (Final Assembly, Test, and Pack) operations are designed to meet the high-precision, high-reliability demands of today’s consumer electronics. We collaborated with the best system integrators in the world for automation solutions, and we support a wide range of advanced assembly processes, including precision glue dispensing and curing—featuring dynamic path adjustment guided by a Keyence laser system to ensure consistent bead placement even on dimensionally variable parts. Our capabilities also include PSA and HAF film activation with controlled temperature profiles for strong, reliable bonds, as well as complex flex bending and assembly for compact designs. We provide in-house laser welding and solder jetting solutions for robust, clean electrical and mechanical joints, as well as hot bar soldering and mechanical fastening for various component integration needs. To ensure the highest quality, we implement automated optical inspection (AOI) at key stages and conduct a comprehensive suite of reliability tests—including WLT (Water Leak Test), ALT (Air Leak Test), drop test, thermal cycling, heat soak, and sweat immersion—to validate product durability under real-world conditions. Finally, our packaging solutions are fully integrated into the assembly line to ensure efficiency, traceability, and product protection from assembly to shipment.

Let us help

Interested in building your consumer product? Contact us now with our solution experts

This website uses cookies.

We use cookies to analyze website traffic and optimize your website experience. By accepting our use of cookies, your data will be aggregated with all other user data.